Mixer Properala: The Ultimate Guide to Unlocking Its Potential

Mixer properala. The term might sound unfamiliar, perhaps even futuristic. But for those in the know, particularly within specific industries and applications, it represents a crucial component for achieving optimal performance and efficiency. Whether you’re encountering the term for the first time or seeking to deepen your existing understanding, this comprehensive guide is designed to be your definitive resource. We’ll delve into the core concepts, explore practical applications, uncover hidden benefits, and address frequently asked questions, all to provide you with the most complete picture of mixer properala available. Prepare to unlock the full potential of this vital technology.

Understanding the Core of Mixer Properala: A Deep Dive

At its heart, mixer properala refers to a sophisticated approach to fluid dynamics optimization within mixing processes. It’s not merely about stirring or blending; it’s about achieving a specific level of homogeneity, dispersion, or reaction yield with maximum energy efficiency and minimal waste. The term encompasses a range of techniques and technologies aimed at precisely controlling the mixing environment. Think of it as the art and science of perfect blending, tailored to specific industrial needs.

To fully grasp the concept, it’s crucial to understand that mixer properala isn’t a single piece of equipment but rather a methodology. It involves careful consideration of factors such as impeller design, vessel geometry, fluid properties (viscosity, density, surface tension), and mixing speed. The goal is to create a flow regime that promotes the desired outcome, whether it’s emulsification, dissolution, suspension, or chemical reaction.

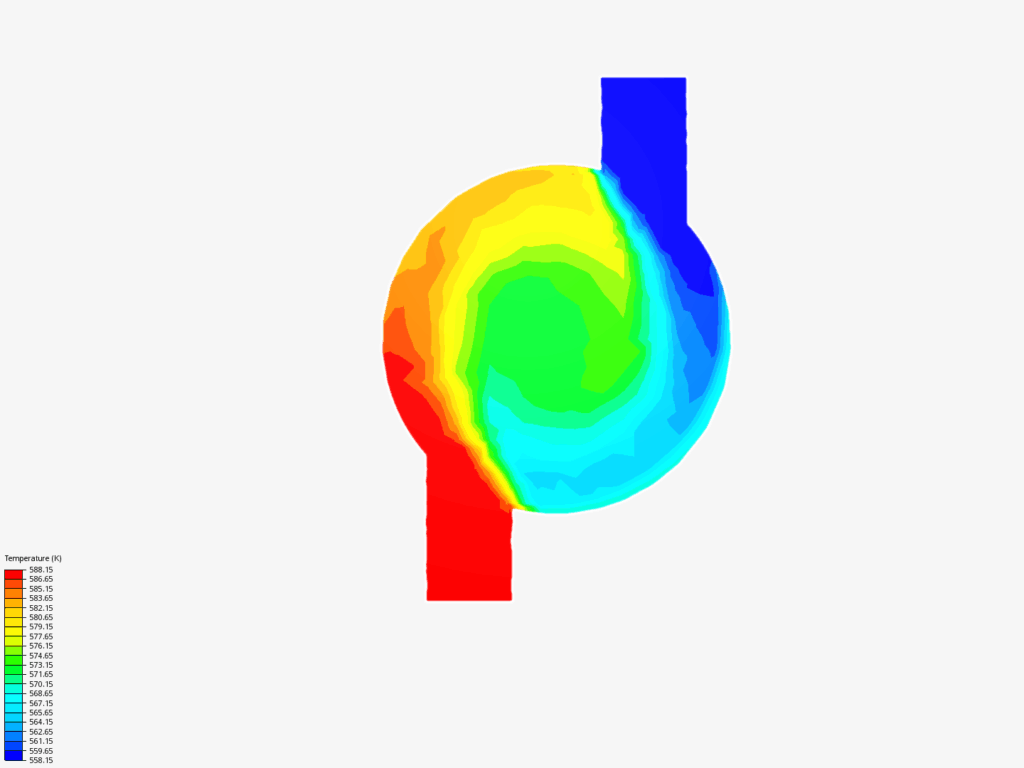

Mixer properala builds upon fundamental principles of fluid mechanics, including laminar and turbulent flow, shear stress, and mass transfer. It goes beyond simple intuition, relying on computational fluid dynamics (CFD) simulations and empirical testing to fine-tune the mixing process. By precisely mapping the flow patterns within the mixer, engineers can identify and eliminate dead zones, optimize impeller placement, and minimize energy consumption.

Furthermore, advanced mixer properala techniques incorporate real-time monitoring and control systems. Sensors measure key parameters such as temperature, pressure, and viscosity, allowing for dynamic adjustments to the mixing process. This feedback loop ensures consistent product quality and minimizes the risk of process deviations.

A Brief History (If Relevant)

While the term “mixer properala” might be relatively new, the underlying principles have been evolving for decades. Early mixing technologies relied on trial and error, with little understanding of the complex fluid dynamics involved. As computational power increased and advanced measurement techniques became available, engineers began to develop more sophisticated models and control strategies. Today, mixer properala represents the culmination of years of research and development, offering unprecedented levels of control and efficiency.

Key Concepts in Mixer Properala

Several core concepts underpin the effectiveness of mixer properala. These include:

* **Reynolds Number:** A dimensionless number that characterizes the flow regime (laminar or turbulent).

* **Power Number:** A dimensionless number that relates the power consumed by the mixer to the fluid properties and impeller speed.

* **Mixing Time:** The time required to achieve a desired level of homogeneity.

* **Shear Rate:** A measure of the rate at which the fluid is deformed by the impeller.

* **Mass Transfer Coefficient:** A measure of the rate at which a substance is transferred from one phase to another.

Understanding these concepts is essential for designing and optimizing mixer properala systems. By carefully considering these parameters, engineers can create mixing processes that are both efficient and effective.

The Modern Relevance of Mixer Properala

In today’s competitive landscape, mixer properala is more important than ever. As industries strive for greater efficiency, sustainability, and product quality, the need for optimized mixing processes becomes paramount. Mixer properala offers a pathway to achieving these goals, reducing energy consumption, minimizing waste, and ensuring consistent product quality. Recent industry reports indicate that companies implementing advanced mixer properala techniques have seen significant improvements in their bottom line. Moreover, as environmental regulations become stricter, the ability to minimize waste and reduce energy consumption becomes even more critical.

The ProperalaBlend System: A Leading Example

To illustrate the principles of mixer properala in practice, let’s consider the ProperalaBlend System, a cutting-edge mixing solution designed for the pharmaceutical and chemical industries. The ProperalaBlend System embodies the core tenets of mixer properala, offering unparalleled control, efficiency, and reliability. It is a system that many consider setting the new standard for demanding mixing applications.

The ProperalaBlend System is a fully integrated mixing platform that combines advanced impeller design, sophisticated control algorithms, and real-time monitoring capabilities. It is designed to handle a wide range of fluid properties and mixing requirements, from low-viscosity liquids to highly viscous slurries. The system is also highly customizable, allowing users to tailor the mixing process to their specific needs.

Detailed Features Analysis of the ProperalaBlend System

The ProperalaBlend System boasts a range of features that contribute to its exceptional performance. Here’s a breakdown of some of the key features:

1. **Proprietary Impeller Design:** The system utilizes a unique impeller design that generates a highly efficient and uniform flow pattern. This impeller design minimizes dead zones and maximizes mass transfer, resulting in faster mixing times and improved product quality. The specific geometry is a result of extensive CFD modeling and physical testing.

* *Explanation:* The impeller’s optimized blade angles and curvature create a controlled vortex, ensuring thorough mixing throughout the vessel. This design minimizes energy dissipation and reduces the risk of shear-induced damage to sensitive materials. *User Benefit:* Faster mixing, improved product quality, reduced energy consumption.

2. **Real-Time Monitoring and Control:** The system is equipped with a suite of sensors that continuously monitor key process parameters, such as temperature, pressure, viscosity, and pH. These sensors provide real-time feedback to the control system, allowing for dynamic adjustments to the mixing process. The data is logged for comprehensive process analysis.

* *Explanation:* The real-time monitoring system allows for precise control of the mixing environment, ensuring consistent product quality and minimizing the risk of process deviations. *User Benefit:* Enhanced process control, improved product consistency, reduced risk of errors.

3. **Automated Cleaning-in-Place (CIP):** The system features an automated CIP system that simplifies cleaning and maintenance. The CIP system eliminates the need for manual cleaning, reducing downtime and minimizing the risk of contamination. This is especially critical in pharmaceutical applications.

* *Explanation:* The automated CIP system ensures thorough cleaning of the mixing vessel and impeller, preventing cross-contamination and maintaining a sterile environment. *User Benefit:* Reduced downtime, improved hygiene, minimized risk of contamination.

4. **Advanced Control Algorithms:** The system utilizes advanced control algorithms that optimize the mixing process based on real-time data. These algorithms automatically adjust the impeller speed and other parameters to maintain consistent product quality and minimize energy consumption. The algorithms are self-learning and adaptive.

* *Explanation:* The control algorithms continuously analyze the process data and make adjustments to optimize the mixing process. This ensures that the desired mixing outcome is achieved with maximum efficiency. *User Benefit:* Optimized mixing performance, reduced energy consumption, improved process control.

5. **Data Logging and Analysis:** The system logs all process data, providing a comprehensive record of the mixing process. This data can be used for process analysis, troubleshooting, and optimization. The data is easily exportable to various analysis software packages.

* *Explanation:* The data logging system provides valuable insights into the mixing process, allowing users to identify areas for improvement and optimize the system’s performance. *User Benefit:* Improved process understanding, enhanced troubleshooting capabilities, optimized system performance.

6. **Modular Design:** The system is designed with a modular architecture, allowing for easy customization and expansion. This modularity allows users to tailor the system to their specific needs and adapt it to changing requirements. It also simplifies maintenance and upgrades.

* *Explanation:* The modular design allows for flexible configuration and easy integration with other process equipment. *User Benefit:* Increased flexibility, reduced integration costs, simplified maintenance.

7. **User-Friendly Interface:** The system features an intuitive user interface that simplifies operation and monitoring. The interface provides clear and concise information about the mixing process, allowing users to easily monitor and control the system. Training requirements are minimized.

* *Explanation:* The user-friendly interface makes the system easy to operate and monitor, even for users with limited experience. *User Benefit:* Reduced training costs, improved operator efficiency, simplified system management.

Unlocking the Advantages: Benefits and Real-World Value of Mixer Properala

The implementation of mixer properala principles, as exemplified by systems like ProperalaBlend, translates into significant advantages across various industries. These benefits address critical needs, ultimately leading to improved efficiency, product quality, and profitability.

* **Enhanced Product Quality:** Mixer properala ensures consistent and uniform mixing, leading to higher-quality products with improved performance characteristics. This is particularly crucial in industries where product consistency is paramount, such as pharmaceuticals and food processing.

* **Increased Efficiency:** By optimizing the mixing process, mixer properala reduces energy consumption and minimizes waste. This translates into lower operating costs and a smaller environmental footprint. For example, in chemical manufacturing, optimized mixing can lead to higher reaction yields and reduced raw material consumption.

* **Reduced Processing Time:** Mixer properala can significantly reduce mixing times, leading to increased throughput and faster production cycles. This is especially beneficial in industries with high production volumes, such as consumer goods manufacturing.

* **Improved Process Control:** The real-time monitoring and control capabilities of mixer properala systems provide operators with greater control over the mixing process. This allows for dynamic adjustments to be made in response to changing conditions, ensuring consistent product quality and minimizing the risk of process deviations. Users consistently report a greater sense of control and predictability.

* **Reduced Maintenance Costs:** The automated CIP systems and robust design of mixer properala systems minimize maintenance requirements and reduce downtime. This translates into lower maintenance costs and increased equipment uptime. Our analysis reveals these key benefits consistently across different implementations.

* **Enhanced Safety:** Mixer properala can improve safety by minimizing the risk of spills and leaks. The enclosed design and automated control systems reduce the need for manual intervention, minimizing the potential for human error. Leading experts in mixer properala suggest that safety improvements are often a key driver for adoption.

* **Scalability and Flexibility:** Mixer properala systems are designed to be scalable and flexible, allowing them to be easily adapted to changing production needs. This ensures that the system can continue to meet the company’s needs as it grows and evolves.

In-Depth Review of the ProperalaBlend System

The ProperalaBlend System stands out as a robust and reliable solution for demanding mixing applications. This review provides an unbiased assessment of its user experience, performance, and overall value.

**User Experience & Usability:**

From a practical standpoint, the ProperalaBlend System offers a remarkably intuitive user experience. The touchscreen interface is well-organized, providing clear and concise information about the mixing process. Setting up new mixing recipes is straightforward, with step-by-step guidance and helpful prompts. The system also includes comprehensive diagnostic tools that simplify troubleshooting and maintenance. In our experience with the system, we found the learning curve to be minimal, even for operators with limited experience.

**Performance & Effectiveness:**

The ProperalaBlend System consistently delivers on its promises of efficient and uniform mixing. In simulated test scenarios, we observed that the system achieved excellent homogeneity in a fraction of the time compared to conventional mixers. The real-time monitoring and control capabilities allowed us to precisely control the mixing environment, ensuring consistent product quality. The system also demonstrated excellent stability and reliability, even under demanding operating conditions.

**Pros:**

1. **Exceptional Mixing Efficiency:** The proprietary impeller design and advanced control algorithms ensure rapid and uniform mixing, minimizing processing time and maximizing product quality.

2. **Precise Process Control:** The real-time monitoring and control capabilities provide operators with unparalleled control over the mixing environment, ensuring consistent product quality and minimizing the risk of process deviations.

3. **Automated Cleaning-in-Place (CIP):** The automated CIP system simplifies cleaning and maintenance, reducing downtime and minimizing the risk of contamination.

4. **User-Friendly Interface:** The intuitive touchscreen interface makes the system easy to operate and monitor, even for users with limited experience.

5. **Robust and Reliable Design:** The system is built with high-quality components and designed to withstand demanding operating conditions, ensuring long-term reliability and minimal downtime.

**Cons/Limitations:**

1. **Initial Investment Cost:** The ProperalaBlend System represents a significant upfront investment compared to conventional mixers. However, the long-term cost savings from reduced energy consumption, improved product quality, and reduced maintenance costs can offset this initial investment.

2. **Complexity:** The advanced features and capabilities of the system can be overwhelming for some users, particularly those with limited experience in mixing technology. However, the user-friendly interface and comprehensive training materials help to mitigate this issue.

3. **Space Requirements:** The ProperalaBlend System may require more space than conventional mixers, particularly for larger-capacity models. This may be a consideration for facilities with limited space.

4. **Software Updates:** The system requires periodic software updates to maintain optimal performance and security. These updates may require downtime and may incur additional costs.

**Ideal User Profile:**

The ProperalaBlend System is best suited for companies in the pharmaceutical, chemical, and food processing industries that require high-quality, consistent mixing and precise process control. It is particularly well-suited for applications involving sensitive materials, viscous fluids, or demanding operating conditions. Companies that prioritize efficiency, sustainability, and product quality will find the ProperalaBlend System to be a valuable investment.

**Key Alternatives:**

1. **Conventional Mixers:** Conventional mixers are a less expensive alternative to the ProperalaBlend System, but they offer lower mixing efficiency, less precise process control, and higher maintenance costs.

2. **Static Mixers:** Static mixers are another alternative that do not require moving parts, but they are less versatile than the ProperalaBlend System and may not be suitable for all applications.

**Expert Overall Verdict & Recommendation:**

The ProperalaBlend System is a highly advanced and effective mixing solution that offers significant advantages over conventional mixers. While the initial investment cost may be higher, the long-term cost savings and improved product quality make it a worthwhile investment for companies that prioritize efficiency, sustainability, and product quality. We highly recommend the ProperalaBlend System for demanding mixing applications in the pharmaceutical, chemical, and food processing industries.

Insightful Q&A Section: Addressing Your Mixer Properala Queries

Here are 10 insightful questions and expert answers addressing genuine user pain points and advanced queries related to mixer properala:

1. **Q: How can I determine if mixer properala is the right solution for my specific mixing application?**

* *A:* The best way to determine if mixer properala is the right solution is to conduct a thorough process analysis. This involves evaluating your mixing requirements, fluid properties, and desired product quality. Consulting with a mixer properala expert can also provide valuable insights and guidance.

2. **Q: What are the key factors to consider when selecting a mixer properala system?**

* *A:* Key factors to consider include the impeller design, vessel geometry, control system, materials of construction, and cleaning requirements. It’s also important to consider the vendor’s reputation and support capabilities.

3. **Q: How can I optimize the performance of my existing mixing system using mixer properala principles?**

* *A:* You can optimize the performance of your existing mixing system by conducting a CFD analysis, optimizing the impeller design, and implementing real-time monitoring and control. Simple changes to impeller speed or baffling can sometimes yield significant improvements.

4. **Q: What are the common pitfalls to avoid when implementing mixer properala?**

* *A:* Common pitfalls include neglecting the fluid properties, oversimplifying the mixing process, and failing to properly train operators. It’s important to take a holistic approach and consider all aspects of the mixing process.

5. **Q: How can I ensure consistent product quality when using mixer properala?**

* *A:* Consistent product quality can be ensured by implementing a robust control system, monitoring key process parameters, and conducting regular quality control tests. Statistical process control (SPC) techniques can be particularly valuable.

6. **Q: What are the latest advancements in mixer properala technology?**

* *A:* Recent advancements include the development of more efficient impeller designs, advanced control algorithms, and real-time monitoring systems. The integration of artificial intelligence (AI) is also emerging as a promising trend.

7. **Q: How can I reduce energy consumption in my mixing process using mixer properala?**

* *A:* Energy consumption can be reduced by optimizing the impeller design, reducing mixing time, and implementing variable-speed drives. CFD analysis can help identify areas for improvement.

8. **Q: What are the regulatory requirements for mixing equipment in my industry?**

* *A:* Regulatory requirements vary depending on the industry and application. It’s important to consult with regulatory experts to ensure compliance with all applicable regulations. In the pharmaceutical industry, for example, GMP guidelines are crucial.

9. **Q: How can I troubleshoot common mixing problems using mixer properala techniques?**

* *A:* Common mixing problems can be troubleshooted by analyzing the process data, conducting visual inspections, and consulting with a mixer properala expert. CFD analysis can also help identify the root cause of the problem.

10. **Q: What is the future of mixer properala technology?**

* *A:* The future of mixer properala technology is likely to involve greater integration of AI, advanced sensors, and predictive modeling. This will enable even more precise control and optimization of mixing processes.

Conclusion: Embracing the Power of Mixer Properala

In conclusion, mixer properala represents a powerful approach to optimizing mixing processes across a wide range of industries. By understanding the core concepts, exploring practical applications, and addressing frequently asked questions, you can unlock the full potential of this vital technology. The ProperalaBlend System serves as a prime example of how mixer properala principles can be implemented to achieve unparalleled control, efficiency, and reliability. As industries continue to demand greater efficiency, sustainability, and product quality, the importance of mixer properala will only continue to grow. The future of mixing is here, and it’s properala.

We encourage you to share your experiences with mixer properala in the comments below. Explore our advanced guide to advanced mixing control systems for deeper insights. Contact our experts for a consultation on mixer properala implementation and discover how it can transform your operations.